Health & Safety in Asbestos Management

At H&S Asbestos we recognise the need to comply with all Health and Safety legislation and strive to attain the highest standards.

As a fully licensed asbestos contractor, we strictly comply with all UK asbestos regulations and implement robust SHEQ (Safety, Health, Environment and Quality) procedures to protect our staff, clients, and the public.

Our dedicated SHEQ team conducts regular site audits and provides expert guidance to ensure full compliance with Control of Asbestos Regulations 2012 and other relevant legislation. We continually monitor and refine our practices to maintain industry-leading safety standards.

We invest heavily in employee development, offering certified asbestos training courses delivered by respected industry professionals. This ensures our teams can effectively identify, manage, and mitigate asbestos-related risks on site.

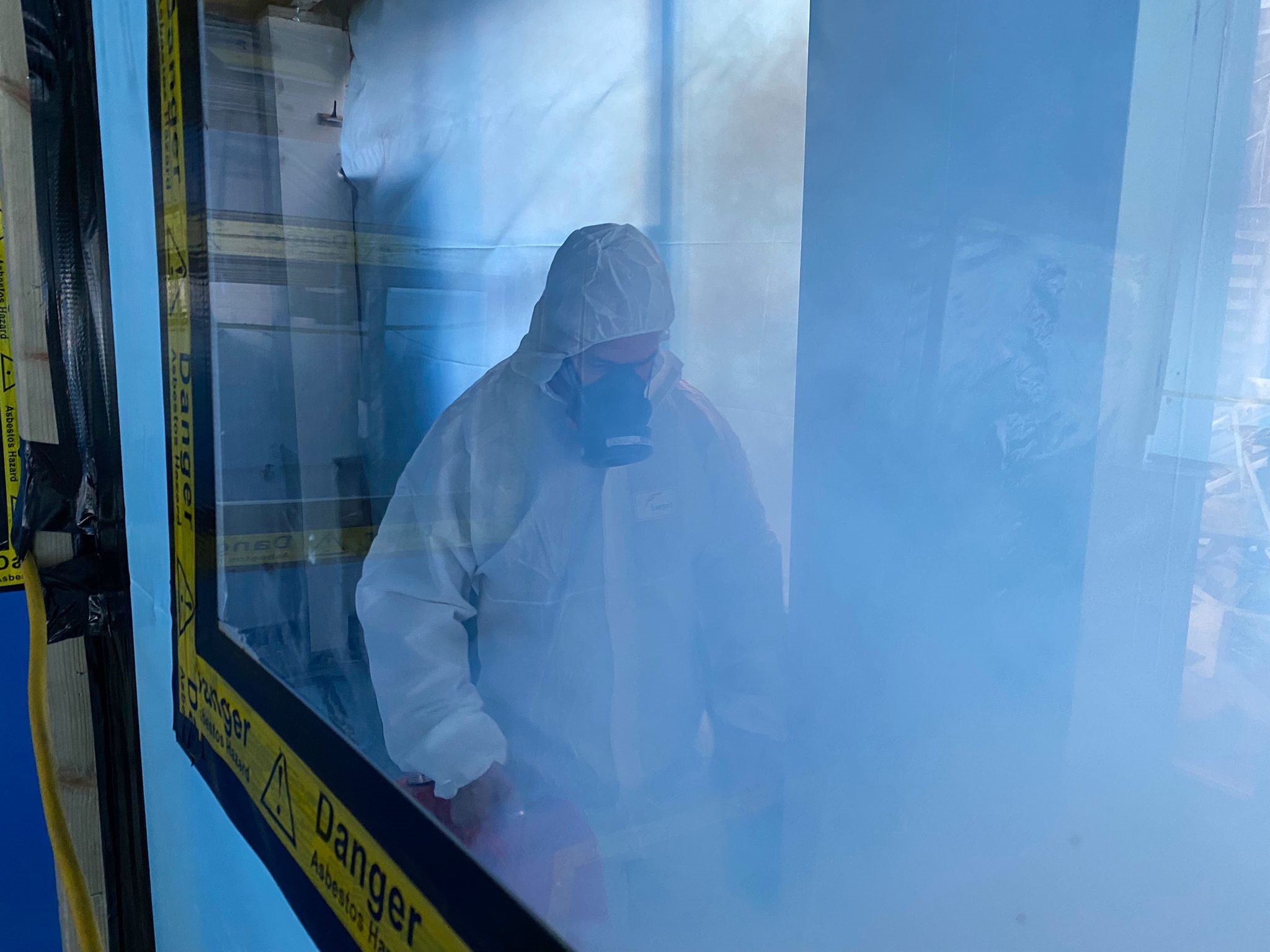

PPE & RPE:

All H&S Asbestos employees are required to wear the following Personal Protective Equipment (PPE) and Respiratory Protective Equipment (RPE) for their own safety as well as the safety of others. All PPE and RPE are inspected before use to ensure compliance with current asbestos safety protocols.

For Non-Enclosure Works:

- Hard hat

- Safety goggles or eye protection

- High-visibility vest

- Task specific gloves

- Steel toe and midsole boots

- Ear defenders

For Enclosure Works:

- Full-face positive pressure respirators

(P3-rated filters) - Half-mask respirators (P3-rated filters)

- Disposable socks and underwear

- Disposable overalls with elasticated hood and cuffs

- Non-laced steel toecap and midsole boots

- Disposable gloves

Project Documentation:

A detailed and thorough programme of removal works is drawn up between all relevant parties with consideration given to any foreseeable issues, such as, site access, time restrictions, working hours, and vehicle movement times. The asbestos containing materials specified for removal are individually risk assessed and an item-specific plan of work drawn up for each item as required, with all relevant notifications and documents submitted to the HSE and interested parties.

Asbestos Enclosures:

H&S Asbestos removal teams use the existing matrix of a building, additional timber supports where required, 1000-gauge polythene, adhesive cloth tape, spray adhesive and expanding foam to form fully sealed asbestos working enclosure, where required, on our projects.

The enclosures are placed under sufficient negative pressure with all access/egress via 3-stage transitional air and bag locks.

Large viewing panels and/or CCTV is installed to ensure all areas of the asbestos removal works are visible and able to be inspected and managed accordingly.

Smoke Testing & Air Control:

Each asbestos enclosure is subject to a thorough smoke test to ensure sealed and robust containment is in place prior to works commencing. The client’s representative and/or nominated independent analyst is invited to oversee this procedure and asked to sign to say they have witnessed a successful test once achieved.

Air Monitoring & Clearance Analysis

This is a legal requirement as per the Control of Asbestos Regulation 2012 - Regulation 16.

Enclosures must be subject to negative pressure with a minimum airflow of 1,000m3/hour through small enclosures (<120m3), and at least 8 ‘air changes’ per hour in large enclosures.

This is provided by using HEPA filter air movers which are stringently checked on a regular basis to ensure they are 99% efficient.

Good airflow and movement across the work areas is paramount in providing a good mix of air in order to filter out the airborne asbestos fibres.

These units also ensure the enclosures are subject to negative pressure to –5 Pascals. Simply put, this means only clean air can enter the enclosure and contaminated air CANNOT leave the enclosure. Where enclosures are perfectly sealed, the volume of air pulled out must be equal to the volume of air allowed in. In other words, where an enclosure has a series of NPUs intended to move 10,000m3/hour of air, it must be designed to allow 10,000m3/hour in.

On large enclosures this may mean dedicated chambers are used to allow clean air into the enclosures. This means the same amount of clean air can enter the areas as is being filtered out and is good air management.

On completion of the removal work to each enclosure, the nominated independent analyst carries out a 4-stage clearance procedure, involving visual inspections, dust disturbance tests and air sampling as required.

Often, the analysis company is asked to carry out reassurance, background and personal air monitoring throughout the project to ensure works are carried out correctly and there is no risk of the spread of asbestos. Copies of these results and associated certificates are made available on request alongside the 4-stage clearance paperwork from each enclosure.

Required On-Site Documentation

For all Asbestos Removal projects, the following on-site paperwork is required.

- License to remove asbestos

- Insurance documentation

- ACAD certificate of membership

- All Medical, training and competency certification for site personnel

- A relevant Notification be that an ASB5 for licensed removals or ASBNNLW1 for non-notifiable licenced works, when required

- Site specific Risk Assessments and Method Statement (RAMS) will be available to all H & S Asbestos staff

- Method Statement briefing sign of sheets

- Toolbox Talk sheets

- HAVS recording sheets

- Manual handling Sheets

- Daily Diaries

Get An Estimate Today

Protect what matters most from the hidden dangers of asbestos.

Contact H&S Asbestos today for an estimate and take the first step toward a safer environment. Our experienced team is here to answer your questions and provide expert guidance tailored to your specific needs.

“H&S Asbestos provided us with a fantastic service at very short notice within a very specialised environment. They were professional and thorough throughout, and we would have no hesitation in employing their services for future projects.”

Dr Kieran Dineen